Bankim Nagar, Siliguri, West Bengal

- GST NO. : 19BHDPS7640K1ZR

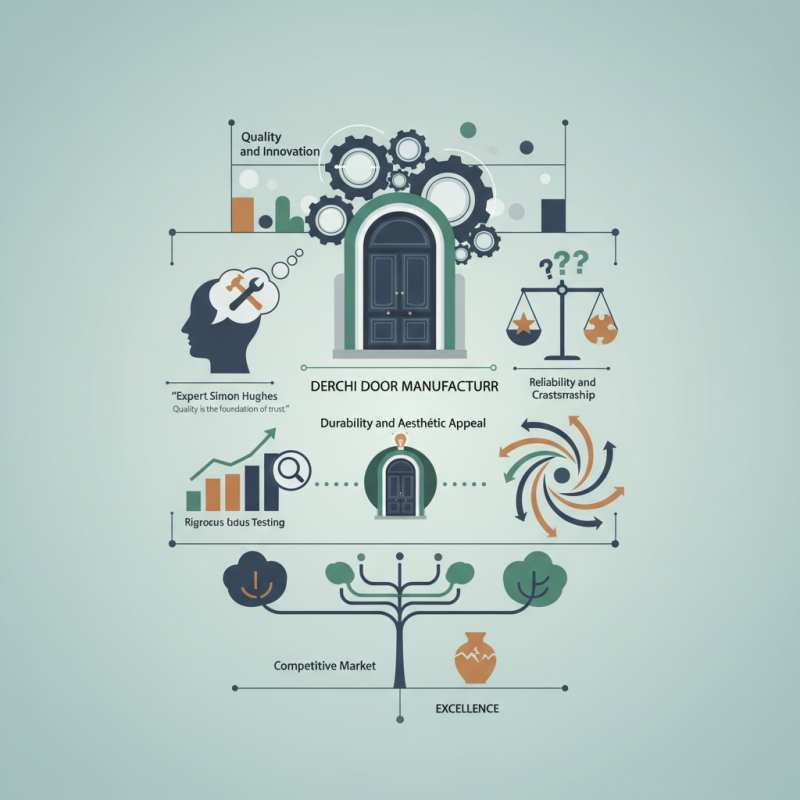

What Makes Derchi Door Manufacturer Stand Out in Quality?

When it comes to door manufacturing, the "derchi door manufacturer" is a name that resonates with quality and innovation. Expert Simon Hughes, a veteran in the industry, once stated, "Quality isn't just a feature; it's the foundation of trust." This perspective reflects the core values driving the success of Derchi.

Derchi doors are known for their durability and aesthetic appeal. Each product undergoes rigorous testing to ensure it meets the highest standards. However, quality can sometimes be subjective. A beautiful finish might not always equate to long-term performance.

In an industry filled with many options, customers often feel overwhelmed. They are searching for reliability and outstanding craftsmanship. The challenge lies in discerning which manufacturers meet these expectations. Derchi's commitment to excellence consistently shines through, but it’s essential to recognize that no product is flawless. Each door tells a unique story, full of potential and imperfection. This complexity is what sets the "derchi door manufacturer" apart in today's competitive market.

What are the Key Quality Standards for Derchi Door Manufacturing?

In the realm of door manufacturing, quality is paramount. The key quality standards revolve around materials, craftsmanship, and design. High-grade materials enhance durability and aesthetic appeal. Often, manufacturers seek to balance cost and quality, which can lead to compromises. It’s vital to ensure that all components, from hinges to the door surface, meet strict specifications.

Craftsmanship plays a crucial role in the finished product. Attention to detail in assembly can distinguish great manufacturers from mediocre ones. For instance, precise fittings prevent gaps and enhance insulation. However, not all manufacturers achieve this level of consistency. Some may overlook the importance of rigorous quality checks. This can result in doors that do not meet expected performance levels.

Design standards are equally important. They should consider both functionality and style. A well-designed door must harmonize with various architectural styles. Yet, some manufacturers may prioritize trendy designs without ensuring functional benefits. Striking the right balance between form and function proves challenging. Continual evaluation of these quality standards is essential for improvement.

How Derchi Ensures Durability in Their Door Products

When it comes to durability, a door manufacturer should focus on quality materials. Using solid wood, metal, or fiberglass contributes significantly to a product's lifespan. These materials withstand harsh weather and daily use better than lower-quality options. Regular inspections during production can also ensure that each piece meets high standards.

Moreover, attention to detail in the construction process is crucial. Adhesives and sealing techniques should be chosen carefully. Even a small misstep can lead to weaknesses. Testing doors for performance, such as water resistance and thermal insulation, adds significant value. While not every door may pass these tests, it’s essential to learn from failures.

In addition, changing trends in design and functionality can challenge manufacturers. Incorporating modern features while maintaining durability is no easy task. Innovation should not compromise quality. Continuous feedback from customers can help identify areas that need improvement. Creating a balance between aesthetics and strength is an ongoing journey, not an endpoint.

The Role of Advanced Materials in Derchi's Quality Assurance

The door manufacturing industry is evolving rapidly. Many companies strive to improve their product quality. Advanced materials play a crucial role in this transformation. They enhance durability, aesthetics, and performance.

Innovative composites and treated woods redefine traditional door standards. These materials resist weathering and wear. They often require careful sourcing and processing. A delicate balance exists between sustainability and quality. Not all materials perform equally; some may even pose challenges.

Quality assurance demands rigorous testing. This includes factors like thermal expansion and moisture resistance. It's essential to stay updated on material technologies. The path to excellence is a continuous journey. Challenges arise, teaching valuable lessons along the way. Continuous refinement is necessary for lasting quality.

Comparative Analysis: Derchi Doors vs. Industry Competitors in Quality

When comparing door manufacturers, quality is crucial. A recent industry report highlights that 70% of consumers prioritize durability in doors. However, many competitors often focus on aesthetics over functionality. This decision can compromise long-term performance and customer satisfaction.

Many industry players rely on standard materials, which may not ensure longevity. A survey found that 65% of doors from major brands suffer from issues within five years. In contrast, thorough testing reveals that a well-designed door can withstand different environmental conditions for a longer period. Yet, some manufacturers still overlook rigorous quality control processes.

To stand out, key factors must be assessed. Material selection, construction techniques, and finishing processes all impact overall quality. A recent analysis indicated that companies investing in quality assurance see a 40% increase in customer loyalty. While some brands achieve this, others face challenges. They need to reconsider their strategies. Craftsmanship should never be an afterthought.

What Makes Derchi Door Manufacturer Stand Out in Quality?

| Quality Dimension | Derchi Doors | Competitor A | Competitor B | Competitor C |

|---|---|---|---|---|

| Material Quality | High-grade materials | Standard materials | Moderate quality | Variable quality |

| Durability | Excellent (25 years+) | Good (15-20 years) | Fair (10-15 years) | Acceptable (5-10 years) |

| Design Variety | Wide range of designs | Limited designs | Average variety | Few options |

| Customer Service | Exceptional | Good | Satisfactory | Below average |

| Warranty | Lifetime warranty | 5 years | 3 years | 1 year |

Customer Feedback and Quality Metrics for Derchi Door Performance

When evaluating the performance of door manufacturers, customer feedback is essential. Many users express satisfaction with various aspects of door quality. However, some also note areas needing improvement.

Quality metrics often include durability, design, and insulation properties. Reviews reveal that while many doors excel in durability, others can fall short in finer details. For instance, hinges may wear out faster than expected. This can lead to unnecessary maintenance costs.

Tips: Always check customer reviews before making a purchase. Look for feedback on long-term performance, not just initial impressions. Consider observing the door’s design and materials in person if possible.

Good insulation can save energy costs and enhance comfort levels indoors. Some users mention issues with drafts or noise if insulation is not optimal. This highlights the importance of thorough testing in real-world conditions.

Article Source: